Design Phase

The initial stage in injection mold and tooling fabrication involves creating a 3D model using CAD (computer-aided design) software. This model serves as the blueprint for the subsequent machining process.

Material Choice

Following the design phase, engineers select a suitable material for the mold or tooling, considering its ability to endure the pressures of the injection molding process and its durability for repeated use.

Surface Preparation

The material is first subjected to surface machining to remove any rough areas or imperfections, ensuring a smooth surface for producing high-quality products.

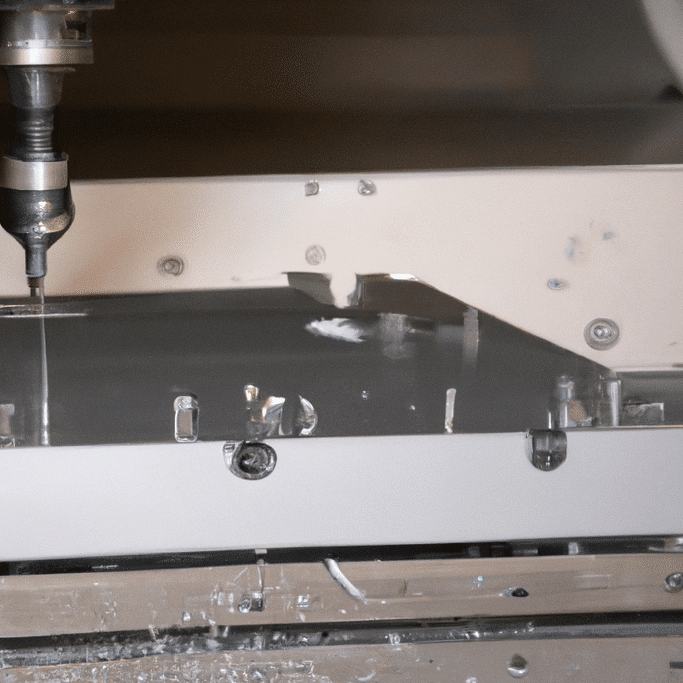

CNC Machining

Precision cutting tools in a CNC (computer numerical control) machine are employed to remove material from the mold or tooling, achieving the desired shape and dimensions after surface preparation.

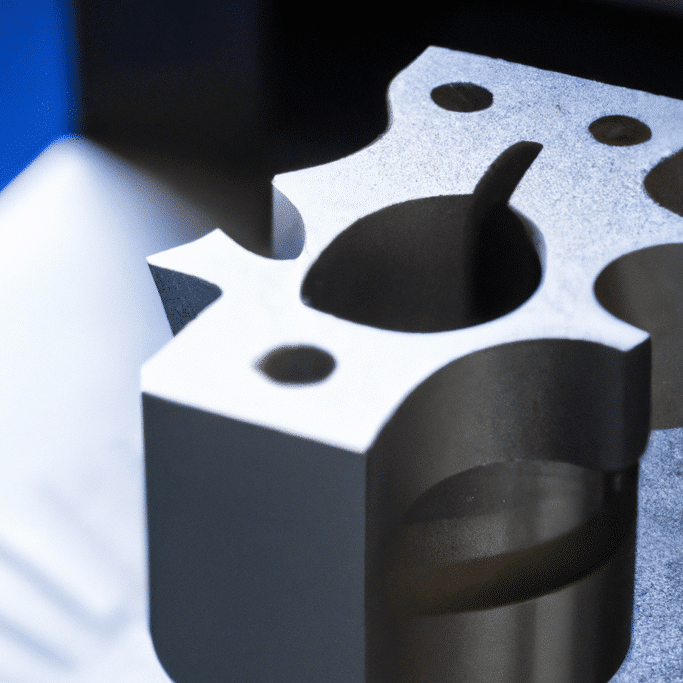

EDM (Electrical Discharge Machining)

For intricate shapes or features unattainable through CNC machining alone, EDM is utilized. This method employs electrical discharges to erode the material and create the desired form.

Engraving

The machined mold or tooling may require engraving, such as identification information or other markings. Laser engravers or other engraving tools can be used for this purpose.

Polishing

The mold or tooling is polished after machining to attain a smooth surface finish, using abrasive materials and compounds to eliminate any remaining imperfections or rough areas.

Inspection

Specialized equipment is used to examine the mold or tooling before its use in the injection molding process, ensuring it meets the necessary specifications by measuring dimensions and tolerances.

Assembly

The final stage involves assembling the mold or tooling and preparing it for the injection molding process, which may include attaching components like ejector pins or cooling channels.

In summary, injection mold and tooling fabrication is a multifaceted process that demands precision, expertise, and meticulous attention at each stage. EDM and polishing are particularly crucial steps, as they guarantee proper shaping and finishing of the mold or tooling, resulting in high-quality products.